Rentals

Get the right trench safety equipment for your project—when you need it, for as long as you need it. Safe Trench Solutions offers a wide range of rental options, ensuring cost-effective access to high-quality shoring systems, trench boxes, and more.

Find the Right Equipment for Your Next Job

Reliable, Compliant, and Cost-Effective Rentals

Renting from Safe Trench Solutions gives you access to high-quality trench safety equipment without the upfront investment.

Our rentals are meticulously inspected, maintained, and certified to meet OSHA, CSA, and industry safety standards.

Whether you need a short-term solution or long-term support, we provide flexible options to fit your project needs while ensuring compliance and peace of mind.

Explore Our Rental Equipment

Explore Our

Rental Equipment

High-Quality Trench Safety Solutions for Every Job

Optimized Shoring Solutions for Every Excavation Need

Choosing a shoring solution for your project can depend on several factors, including depths required, soil stability, pipe diameters and equipment compatibility.

The diagram shows the maximum recommended depths for each of our shoring systems, with options ranging from lightweight trench boxes to slide-rail systems.

Our Shoring Portfolio showcases a comprehensive range of trench safety solutions, each designed to support excavation projects of varying depths and conditions.

Have questions about the right shoring solution? Reach out to your team, and we will provide you the right support in choosing your shoring solution based on your project specifications.

Filter by:

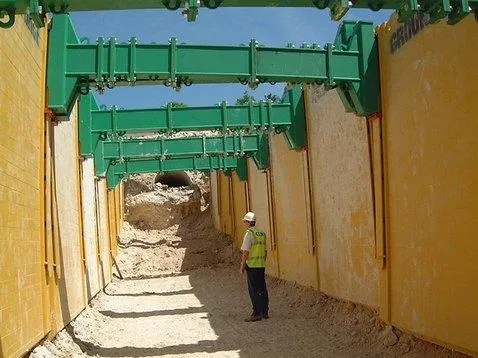

Slide Rail Shoring

With slide rail shoring with rolling struts, the individual shoring components are only combined to form a closed shoring wall when they are actually in the trench.

Plates, slide rails and rolling struts are slidable parallel to one another. The trench remains the same width at all times during the construction phase. This significantly reduces the forces required during installation and removal. There is less vibration and the shoring itself is virtually free of settling.

The rolling struts’ H-shaped design ensures perfect conditions in all work phases. During installation, the rolling strut is in the lower range of the slide rail, providing the excavator operator with a clear view, meaning a short boom can be used.

The large strut clearance heights represent another advantage. These are infinitely adjustable during the pipe-laying process. Distance pieces enable you to realise the required working width. Depending on the depth of the trench, customers can choose between a single, double or triple slide rail trench shoring system.

Single Slide Rail Series 790

With this slide rail system, the shoring plates are only inserted into one guide. This enables shoring depths of up to maximum 3.80m.

Just like all rolling strut systems, when laying longer pipes, the rolling struts can be arranged so their heights are offset, enabling the pipes to be pitched in.

These are primarily used for medium-sized trench constructions with high strut clearances and in environments where there is the risk of settling. Using a soil support enables even larger strut clearance heights to be realised, and our clamping device even enables you to realise strut-free trench shoring pits.

Pits can be closed all around by using corner slide rails and trench shoring plates.

Content via sbh-verbau.de/en/

Double Slide Rail Series 750

With this slide rail system, the shoring plates are inserted into two guides. Thanks to the second guide, during removal, there is no need to remove the entire shoring height at once; just the shoring plates in one guide.

This double slide rail enables you to use different rolling struts, which enables a wide range of applications. When laying longer pipes, the rolling struts can be arranged so their heights are offset, enabling the pipes to be pitched in.

The double slide rails in the 750 series are used for deep trench constructions with high strut clearances and in environments where there is the risk of settling. Using a soil support enables even larger strut clearance heights to be realised, and our clamping device even enables you to realise strut-free trench shoring pits.

Pits can be closed all around by using corner slide rails and trench shoring plates.

Content via sbh-verbau.de/en/

Slide Rail Shoring - special solutions

Pit Shoring

By combining the corner rails with rolling strut frames, you can implement the widest range of pit dimensions.

Strut-free trenches, for example for laying longer pipes, building a structure or for using a pipe jacking machine, can be realised with the clamping device.

If the trench is deeper than the base rail length, you must extend it using extension rails.

Content via sbh-verbau.de/en/

4-sided corner slide rail

The 4-sided corner slide rail is predominantly used for soil replacement works.

Preferably for trench depths up to 3.80m.

Content via sbh-verbau.de/en/

Pile Chamber Shoring

The pile chamber plates, with their side guides, are also used in rolling strut shoring. Where pipes and cables cross the excavated area, there are two options for using pile chamber plates.

Pile chamber with rolling strut shoring and beam;

The pile chamber plate is inserted into the slide rails’ outer guides, and so it is level with the ground surface. Depending on static requirements, one or more beams are inserted into the slide rail’s inner guides, further down.

Pile chamber with rolling strut shoring and slide rail plates;

The pile chamber plate is installed in combination with slide rail plates, whereby the slide rail plates are inserted into the slide rail’s outer guides and the pile chamber plates are inserted in the slide rail’s inner guides, further down.

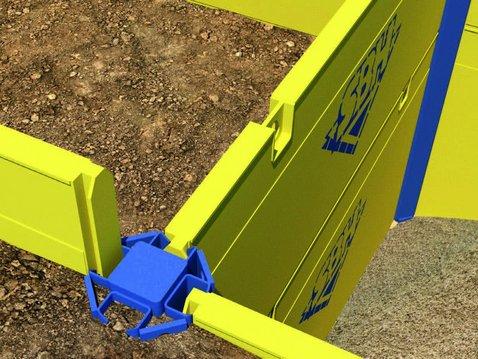

The corner connector provides a friction-locked connection between the pile chamber plates, to form manhole shoring.

Content via sbh-verbau.de/en/

Quick Shore

Quick ShoreSeries 260

SBH’s Quick Shore Series 260 is specifically intended for shoring depths of up to 2 metres.

This system is preferred for laying and repairing house connections, as well as gas and water pipes. As well as construction companies, other users of this practical shoring system are predominantly gardening and landscaping companies, as well as local authority contractors.

The aluminium rails which form part of the Quick Shore system are available in lengths of 1.50 and 2.10m. Infinitely adjustable hydraulic struts are mounted between these rails. The struts are available in four different lengths. Depending on rail length and working width, the entire construction weighs between 33 and 40 kg. Due to its extremely light construction, the trench shoring system can be installed by just one person, without the need for an excavator or lifting gear.

Content via sbh-verbau.de/en/

Aluminium Shoring

Aluminium ShoringSeries 250

Shoring system for minor cable and pipe-laying works and the use of lightweight construction machinery.

SBH Tiefbautechnik’s Aluminium Shoring Series 250 is ideal for minor cable and pipe-laying works and the use of lightweight construction machinery.

SBH’s versatile aluminium shoring can easily be used as a trench edge support, trench box or pit shoring at a depth of up to 2.40m.

The light construction enables quick assembly and easy installation using the place and adjust method. The 60cm-high trench supports can easily be manually transported by two people, and the 2.40m-high aluminium shoring box can be effortlessly installed and removed using a mini-excavator. A complete 2m-long unit weighs only 380 kg.

To fulfil the aluminium shoring’s requirements, special extrusion-pressed profiles have been developed, to ensure the best material performance under extreme working conditions.

Content via sbh-verbau.de/en/

Lightweight Shoring

Lightweight ShoringSeries 100

SBH Tiefbautechnik’s Lightweight Shoring Series 100 is ideal for small to medium-sized trench construction and the use of light construction machinery. Lightweight steel shoring is versatile and can easily be used for supply lines, house connections and cable laying.

Smooth-running struts, flexibly mounted in the plate profile, enable quick assembly and easy installation using the place and adjust method. The shoring system can also be extended, for use in deeper trenches.

Content via sbh-verbau.de/en/

Box Shoring

Box shoring is also suitable for use with unstable soils. Thanks to its spring-mounted spindles, the box shoring can also be installed so it is friction-locked, using the cut and lower method. The box shoring systems are available in a range of plate thicknesses and with various safe working loads.

Light Box Series 300

The SBH Light Box combines lightweight plate construction with a flexible spindle. This type of shoring is therefore ideal for small to medium-sized trench shoring projects and the use of light construction machinery. The shoring system can also be used in unstable soils. Thanks to its flexible spindle, it can also be installed using the cut and lower method.

The Light Box is primarily used for supply lines, house connections and in cable laying.

Compared with the Lightweight Shoring system, a more robust side profile construction enables higher strut clearances, with the spindles meaning it can be used in wider trenches.

Content via sbh-verbau.de/en/

Standard Box Series 600

The SBH Standard Box is the titan of trench shoring systems.

This robust, long-lasting shoring box features an extremely reinforced top, which can resist even the high loads that occur when using the cut and lower method. At the same time, the sturdy plate cutting edge enables even firm soil to be cut away.

To minimise deformation, the side elements feature additional bars. The use of flexible spindles enables this system to be used in unstable soils, using the cut and lower method.

It is predominantly used for laying supply lines to a depth of up to 4m. The permitted working loads far exceed expected typical construction site conditions. For maximum safety of your civil engineering projects.

Content via sbh-verbau.de/en/

Standard Box with transformation profile Series 600

SBH’s transformation profile combines base and top plates to form a shoring box whose strut clearance height is roughly the same as the base plate height. This makes it possible to achieve greater strut clearance heights with the same shoring boxes, without having to switch to other types of shoring.

A further advantage is that the box can be transported in individual parts, and only assembled into a finished shoring box at the construction site. This means that no special transport is required.

The transformation profile slides over the posts on the base plate and top plate, and is then pinned in place. Four sturdy, square-profile struts provide the support. The fully integrated spring spindles are pinned to the transformation profile, enabling the shoring box to be installed using the cut and lower method.

Content via sbh-verbau.de/en/

Drag Box Series 650

The Drag Box has been designed for trench shoring projects in open terrain and with stable soils, and only secures a small area for laying the pipes. The end faces remain unshored, and must be sloped according to ground conditions.

Further excavation of soil takes place ahead, and the Drag Box is pulled through the excavated trench to the new working position. The area behind the box is filled and compacted, while pipe laying occurs in the area protected by the shoring plates.

Recommended

- In open terrain

- No pipes/cables crossing

- Where it cannot be affected by buildings and physical structures

- Where it cannot be affected by roads or thoroughfares and away from endangered cables

- In temporary stable soils

- In dry ground

- With mechanical compacting from above

- When settlement can be accepted

Content via sbh-verbau.de/en/

Shoring Spindle 031

Our shoring spindle is used in all our trench boxes: Light Box, Extra Box and Standard Box. SBH Tiefbautechnik’s spindles offer flexible trench widths and maximum safety for your civil engineering projects.

Just like all the other components of our trench shoring systems, the shoring spindles are manufactured in our own factory in Heinsberg, Germany.

SBH spindles are set to the required trench width by simply mounting and pinning extension pipes.

In conventional shoring systems, the extension pipes have to be screwed together. That takes time and requires lots of screws. But with SBH’s solution, you just fit the extension pipes together and pin them – and you’re done! The flexible spring spindle creates the connection between the plates and the spindles. This makes it possible to alternately press the plates down using the cut and lower method.

Both the spindles and extension pipes are extremely robust in their construction, and can therefore withstand high loads. The stated compressive forces have been confirmed by extensive bench tests.

Content via sbh-verbau.de/en/

Maxi Box Series 630

The Maxi Box enables you to lay pipes with extremely large diameters. This box enables you to realise three strut clearance heights, with the maximum strut clearance height being 2.29m. The top is extremely reinforced, in order to resist the high loads when lowering the shoring box. At the same time, the sturdy plate cutting edge enables even firm soil to be cut away.

To minimise deformation, the side elements feature additional bars. The use of the yellow flexible spindle ensures the shoring can resist the high compressive forces. It is predominantly used for laying supply lines to a depth of up to 4m.

Content via sbh-verbau.de/en/

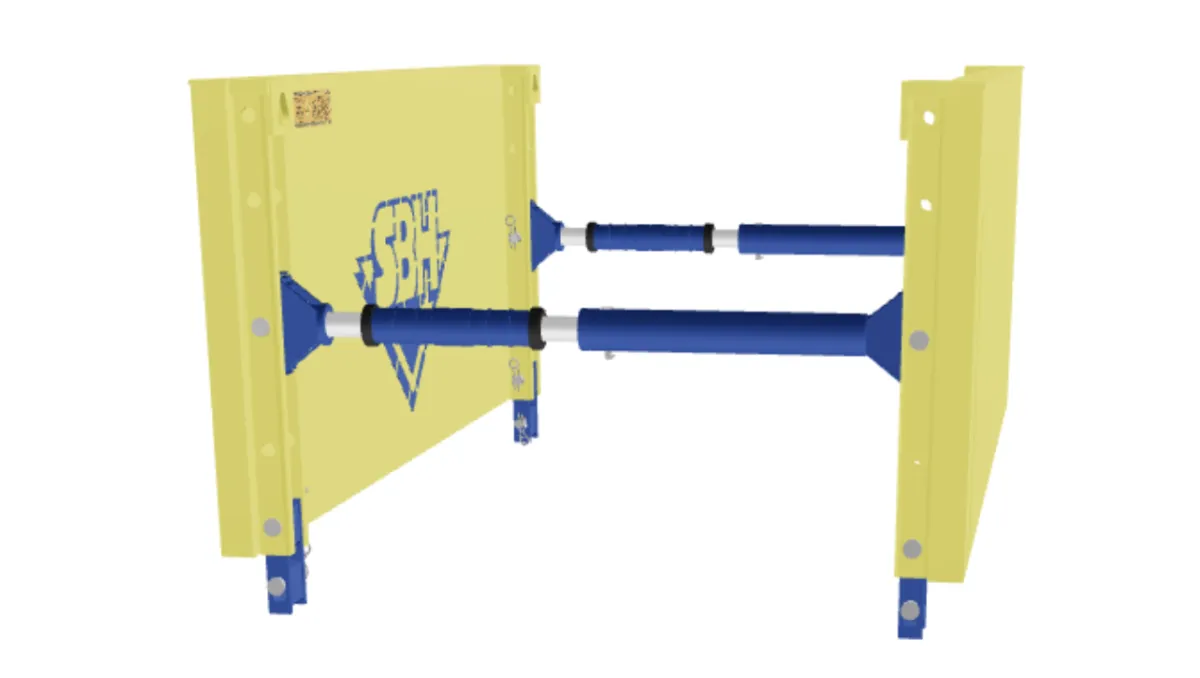

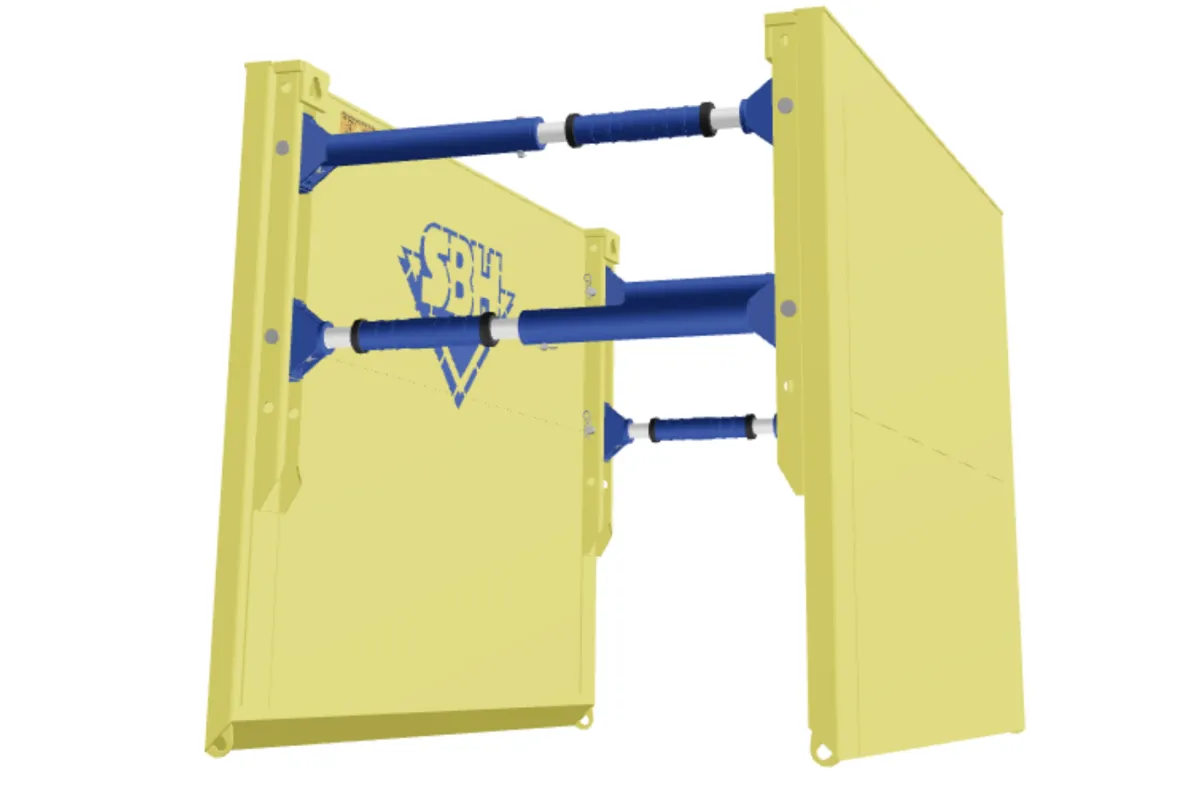

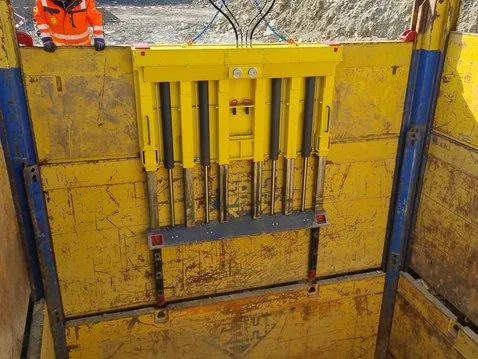

Rolling Strut Box Series 780

With SBH’s Rolling Strut Box, you have a shoring box that also brings with it the advantages of slide rail shoring. The shoring plates are supported by the rolling struts that have long since proven themselves in slide rail trench shoring.

The strut clearance heights are infinitely adjustable, and can so be set according to specific site requirements. Spacer bars enable you to realise the required working width. During installation and removal, each shoring component is individually slidable. Plates and rolling struts are moved parallel to one another.

This significantly reduces the forces required during installation and removal. When laying longer pipes, the rolling struts can be arranged so their heights are offset, enabling the pipes to be pitched in.

This shoring system is predominantly used in trench shoring projects where great strut clearance heights are also required.

Content via sbh-verbau.de/en/

Manhole Box Series 600

The Manhole Box is used when wider areas for manholes need to be created in pipeline trenches.

The plate body is U-shaped, with the wings extending 0.40m into each side of the trench. The result is a 0.8m-wide manhole.

The areas before and after the manhole are secured using normal shoring boxes. The spindles and accessories used are the same as those for the shoring boxes.

Content via sbh-verbau.de/en/

Pile Chamber Shoring

Pile Chamber ShoringSeries 400

Pile chamber shoring is the perfect choice where supply lines cross.

This system combines shoring plates and trench sheets. The pile chamber is also the guiding frame for the trench sheets, and at the same time serves as the upper support.

The excavator can easily press in the trench sheets before excavation takes place. The working width is adjusted by means of SBH spindles and extension pipes.

Upon request, pile chamber plates can also be manufactured for other trench sheets. Please contact us.

Content via sbh-verbau.de/en/

Fall protection railings

Fall protection railings up to 5.5 m depth

SBH’s fall protection railings are a lightweight temporary edge protection system developed for quick, easy, manual installation with a wide range of SBH shoring systems (boxes, trench sheets, H-beams etc). The fall protection railings are supplied in various lengths from 0.5m to 3.5m, with two mounting fixtures. (Various mounting fixture designs are available for the specific products.) The mounting fixtures are infinitely adjustable, and can so be adjusted to different plate and material thicknesses. The individual fall protection railings weigh between 8kg and 38kg, with the mounting fixtures weighing an additional 2.6kg to 3.5kg.

The fall protection railings can be fitted directly to SBH products by two people, by means of the mounting fixtures and clamping bolts. The system fulfils the requirements of BS EN 13374 (2004) Class A ‘Temporary Edge Protection Systems’, and is suitable for use where the maximum site slope is 10°.

Content via sbh-verbau.de/en/

Auxiliary equipment

SBH offers a range of accessories and auxiliary equipment, which makes use and handling of SBH shoring systems enormously easier. Whether that’s lowering an inner-facing slide rail plate with the help of SBH’s lowering aid, or removing a stuck shoring plate with our SBH Hydralifter. SBH therefore makes work on the construction site that bit more effective and efficient, thanks to the aid of other little helpers. Please contact us to enquire about our range of products.

Hydralifter

SBH’s new Hydralifter is the safe equipment for simply and easily removing even the larger shoring plates and rails. Thanks to the integrated hydraulic cylinder with enhanced pulling force of 100 tonnes, even small excavators are able to pull out shoring plates and rails with ease. Both models have been optimised for use with Oilquick, Likufix or other fully hydraulic changing systems, and can similarly be powered by external hydraulic units.

Attention: To use the Hydralifter, you will need an HEM beam. Please observe the usage instructions.

Thanks to the built-in rotary motor, the Hydralifter can be controlled and positioned with the utmost precision. The Hydralifter is operated solely from the excavator’s driver’s cab. Removal is therefore quick, easy and gentle on materials.

Content via sbh-verbau.de/en/

Plate Grab

In trench construction, the Plate Grab enables shoring plates to be safely lifted, pulled out, offset and transported, without time-intensive manual lifting tackle attachment and suspension from chains.

The Plate Grab removes the shoring plate directly, without the need for additional lifting tackle. All the Plate Grab’s functions are directly controlled from the driver’s cab, as is usual with Oilquick and LikuFIX.

Content via sbh-verbau.de/en/

Shoring Box Grab

In trench construction, the Shoring Box Grab enables shoring elements and shoring boxes to be safely lifted, pulled out, offset and transported, without time-intensive manual lifting tackle attachment and suspension from chains.

The Shoring Box Grab removes the shoring box directly, without the need for additional lifting tackle. All the Shoring Box Grab’s functions are directly controlled from the driver’s cab, as is usual with Oilquick and LikuFIX.

Content via sbh-verbau.de/en/

Shoringpress

With the introduction of the shoring press, we are responding to our customers' request to speed up the installation of our slide rail shoring in confined spaces and with light mobile excavators.

The SBH shoring press is used to safely and precisely lower SBH slide rail panels to great depths with light equipment. The shoring press is first connected to the outer shoring panel with bolts in a tension- and pressure-proof manner. Then the shoring panel is pressed into the soil by the stroke length of the press cylinders ih the guides of the slide rail without vibration and with low noise.

Without the use of chains and solely operated by the excavator driver from his platform, the risk potential is reduced to a minimum. The result is not only a significant time and cost saving during shoring removal, but also the safety of the site workers, who do not have to stay in the danger zone.

You can find more useful tools for our shoring systems in the download area.

Content via sbh-verbau.de/en/

Work With Our Engineering Experts Today

Work With Our Engineering Experts

From trench safety assessments to fully engineered shoring solutions, our team is ready to support your project with expertise and precision. Contact us today to discuss your needs and ensure your excavation is safe, compliant, and efficient.